Introduction to Hydrogen Valves

In the current global scenario, where there is an increased demand for green energy, hydrogen has emerged as a potential clean energy source. It can play a critical role in the UK's transformation to a net-zero economy. Hydrogen is used in a wide range of industries, such as Energy and Power generation, transport and fuel. The increased use of hydrogen has led to an increase in demand for specialised hydrogen valves.

Why are specialised Hydrogen Valves needed?

The unique properties of hydrogen, such as its small molecular size and high operating pressure, make standard industrial valves unsafe and ineffective. Valves designed for hydrogen applications must meet more stringent conditions. For example, to overcome problems like metal embrittlement, hydrogen valves must be constructed from specialised materials like Monel, Hastelloy, and 316/316L stainless steel. These specific design considerations are vital to have, otherwise hydrogen can escape through micro leakage paths and degrade materials over time.

New Product Range

The new product range of high-pressure valves for hydrogen systems include check valves, ball valves and needle valves.

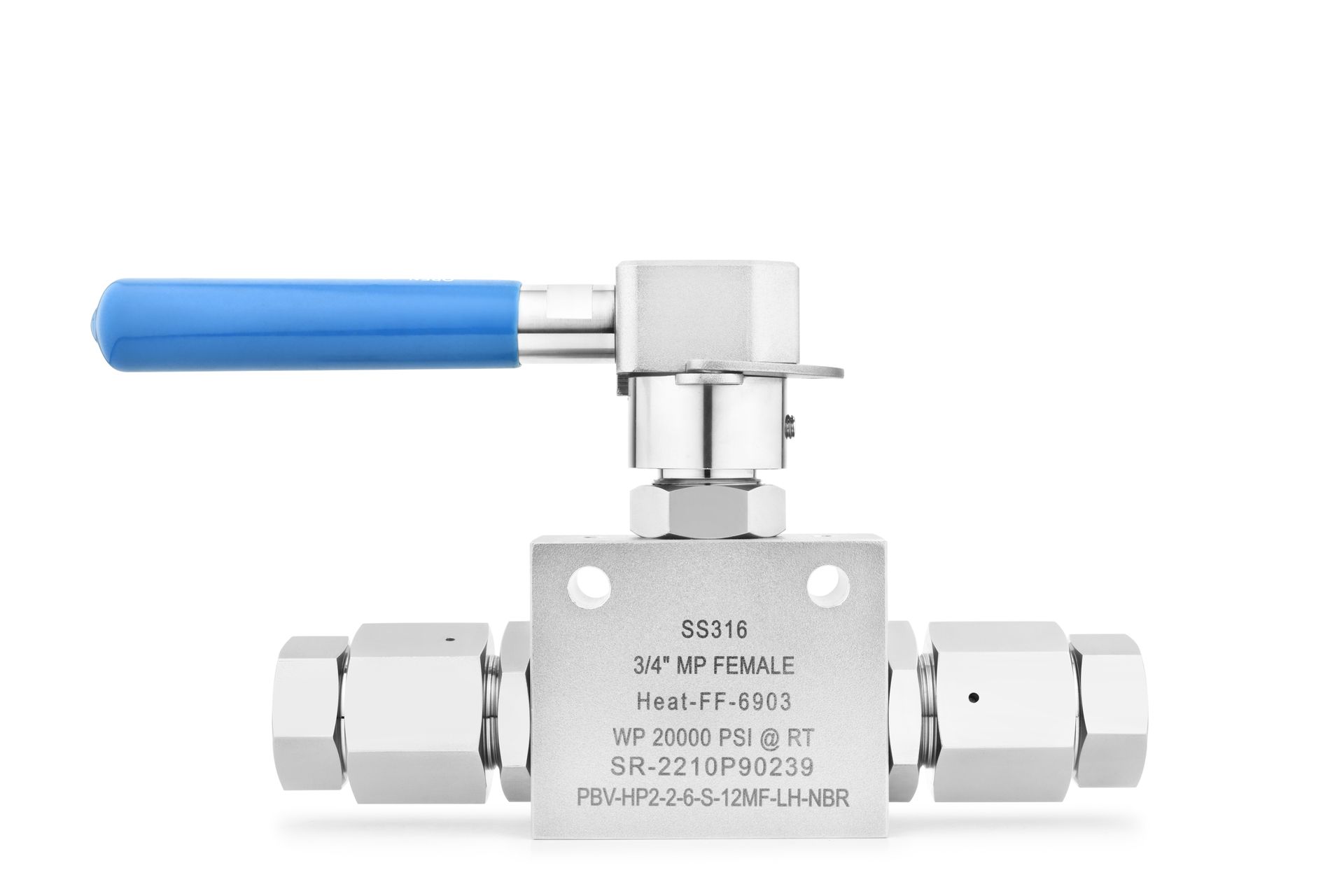

Hydrogen Ball Valves

Ball valves are commonly used in hydrogen systems to control on/off flow and direction between process lines. Careful consideration must be given when choosing ball valve designs for hydrogen application, in particular the stem sealing designs is important as they must be highly resistant to leakage and wear. They often incorporate trunnion – style ball to help maintain consistent and leak tight performances. Another key point about selecting the right ball valve involves considering the configuration and system compatibility. They may be available in 2 – way or 3 – way designs to suit process requirements.

Hydrogen Check Valves

Check valves play a vital safety role with compressor units in refuelling systems which is essential to protecting equipment and end users. They are very different from standard valves as these designs tend to use springs that made from strain- hardened materials which can cause embrittlement and increases the risk of long-term degradation. Due to these challenges ball check valves are a much smarter choice for hydrogen applications. Their designs are simpler therefore the reliance on spring mechanisms reduces and they can deliver reliable sealing performance under dynamic operating conditions.

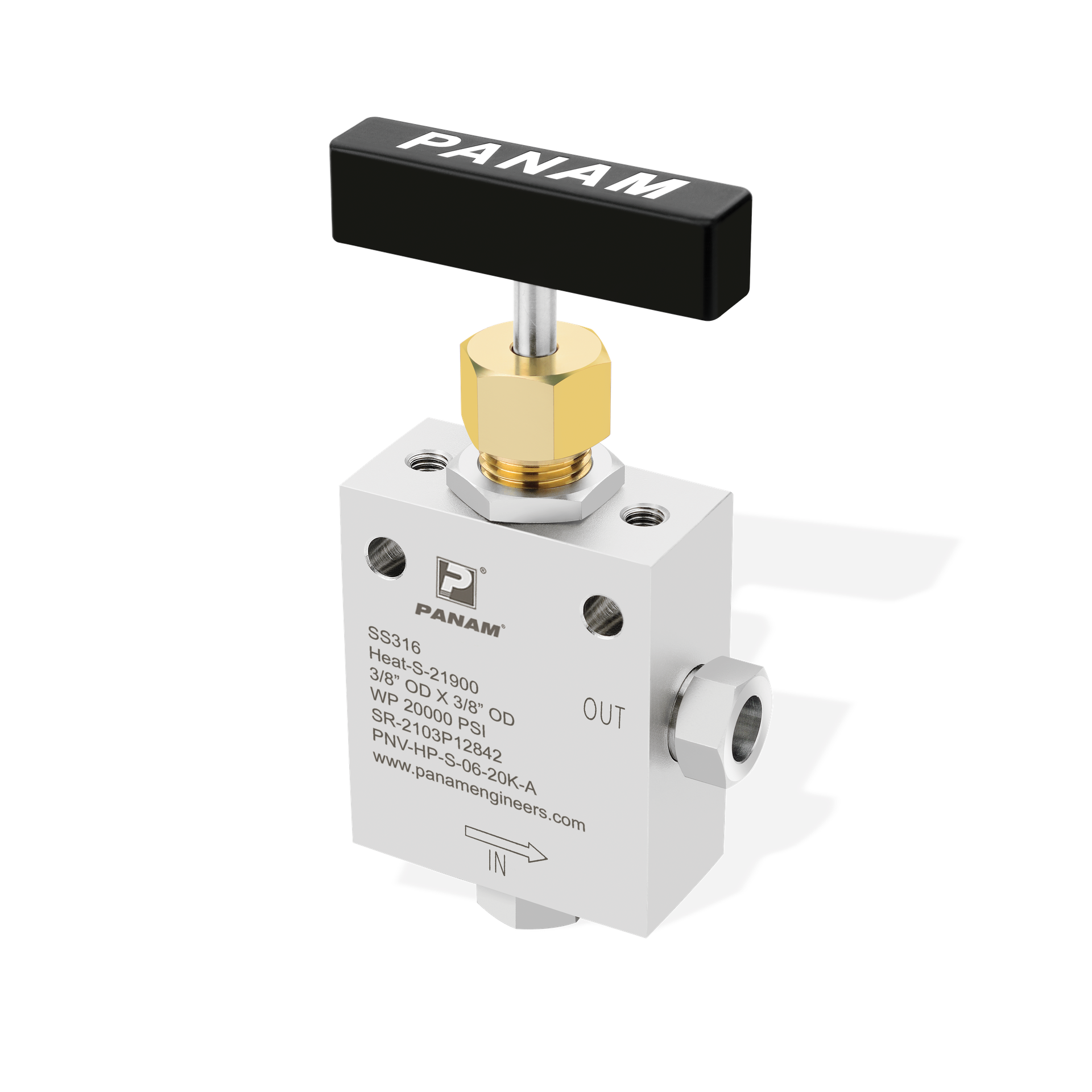

Hydrogen Needle Valves

Needle Valves are specially engineered to meet the demanding requirements of hydrogen systems ensuring superior safety, leak tight performances and durability under extreme pressure. Most needle valve feature all metal construction that requires significant force to achieve a tight shut off. This can also increase the risk of leakage and lead to deformation of the needle. To combat these challenges, it is important to pick needle valves manufactures from high quality 316 stainless steel to improve resistance and prevent degradation from happening during operations. The needle valve must qualify for the elevated pressures commonly associated with hydrogen systems (350 -700) bars and the pressure ratings are just as critical. Making sure there is full compatibility with the system components and hydrogen- rated fittings will ensure reliability, safety and long-term performance.

Features | Specification |

Pressure Rating | Up to 60,000 psi |

Valve types | Needle, Valve, check |

Materials | SS316, Inconel, Hastelloy |

Applications | Hydrogen, Energy, Chemical |

Standards | Industry compliant |

Why Panam Valves Are the Preferred Choice for Hydrogen Systems?

Panam's new high-pressure valves are engineered to overcome these challenges. They undergo precision manufacturing, rigorous testing to ensure they can support hydrogen storage and distribution, refuelling infrastructure and clean energy products.

Panam’s manufacturing processes ensure precise tolerances, robust designs and surface finishes that further mitigate leakage and wear. The use of hydrogen compatible alloys ensures material and results in valves that deliver long-term durability and performance, even in the harshest oil, gas, and energy environments.

With its 25 plus years of engineering expertise, Panam has made a name for itself internationally across the hydrogen, chemical, energy and industrial sectors. They supply valves to over 52 countries worldwide. Customers choose Panam due to their proven track record and ability to provide tailored solutions that meet the demands of modern hydrogen infrastructure.